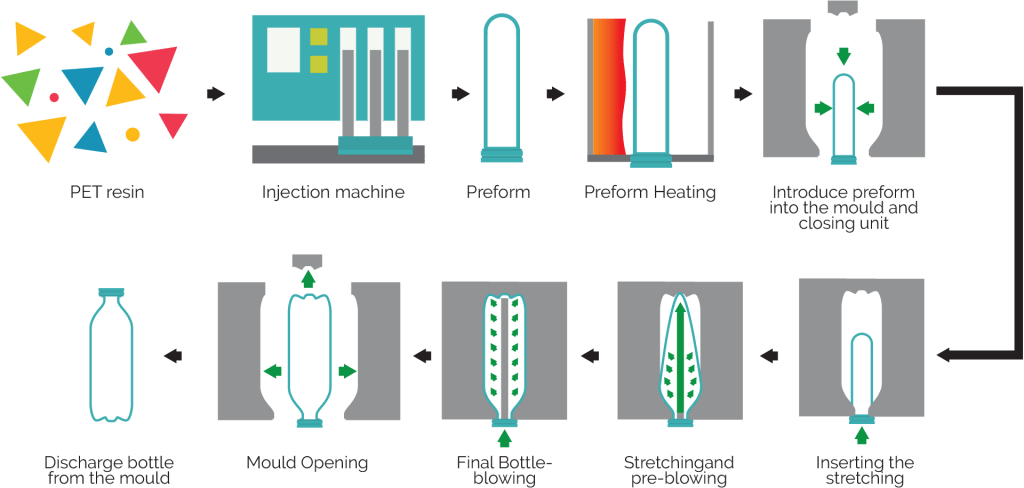

Automatic bottle blowing machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc. Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Features:

It is suitable for producing PET plastic bottles in all shapes. It is widely used to produce the pure water bottle, mineral water bottle, carbonated drink bottle, juice hot fill bottle, oil bottle and so on.

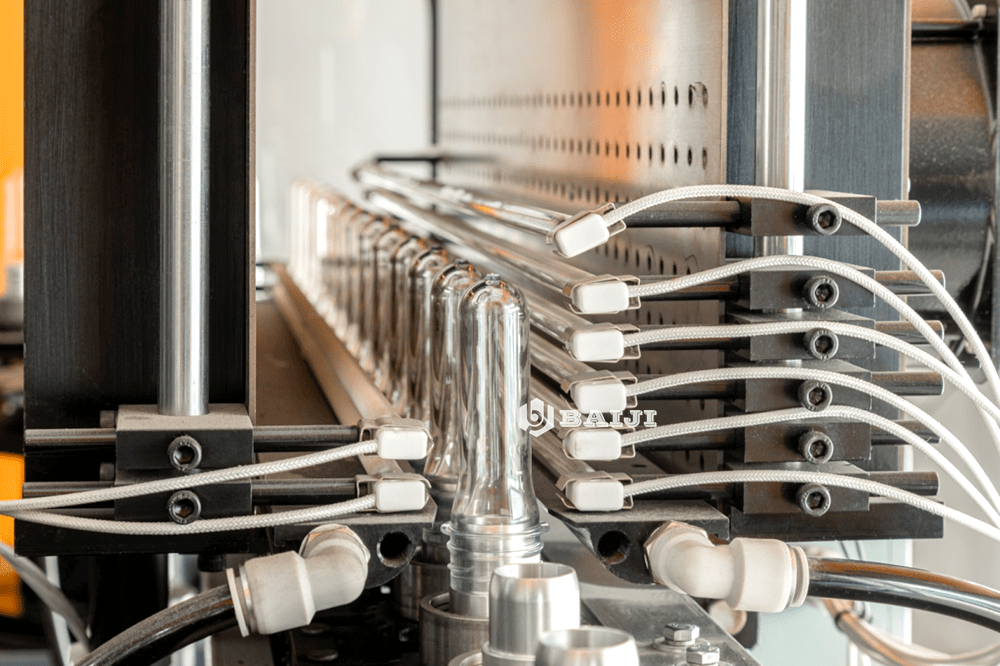

Heating system

Perfect heating system design decrease power consumption.

Special oven design helps power saving and easy maintain.

Each lamp position and temperature can be adjusted.

Cycle air-cooling system keeps the oven temperature constantly.

Servo technology innovation on clamping system & stretching

Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

| Model | 2EL | 4EL | 6E | 6EL | 9E |

| Capacity (500ml/bph) | 2500-3000 | 5500-6000 | 9000-9500 | 8000-8500 | 11000-12000 |

| Max volume | 2L | 2L | 6 cavities for 750ml 3 cavities for 2L | 2L | 9 cavities for 750ml 4 cavities for 1.5L |

| Max neck diameter | 38mm | ||||

| Max bottle diameter | 108mm | 108mm | 70mm | 108mm | 70mm |

| Cavity | 2 | 4 | 6 | 6 | 9 |

| Installation power | 45kw | 96kw | 96kw | 110kw | 110kw |

| Running power | 25kw | 45kw | 45kw | 60kw | 60kw |

| Working pressure | 1.0Mpa | ||||

| Low pressure air consumption | 1.6m³/min | 2.0m³/min | 2.0m³/min | 2.0m³/min | 2.0m³/min |

| Blowing pressure | ≤3.5Mpa | ||||

| High pressure air consumption | 2.4m³/min | 4.8m³/min | 6.0m³/min | 8.0m³/min | 8.0m³/min |

| Dimension(mm) | 3800*1800*1900 | 4500*2300*2600 | 4500*2300*2600 | 5600*2300*2600 | 5600*2300*2600 |

| Weight(kg) | 3000 | 5000 | 5500 | 8000 | 9500 |