The fruit juice drink filling machine is one of the main products of our company. The filling method is gravity hot filling, and the filling temperature is kept about 85-90 degrees or middle temperature 68-72 degree through the temperature control reflux system.

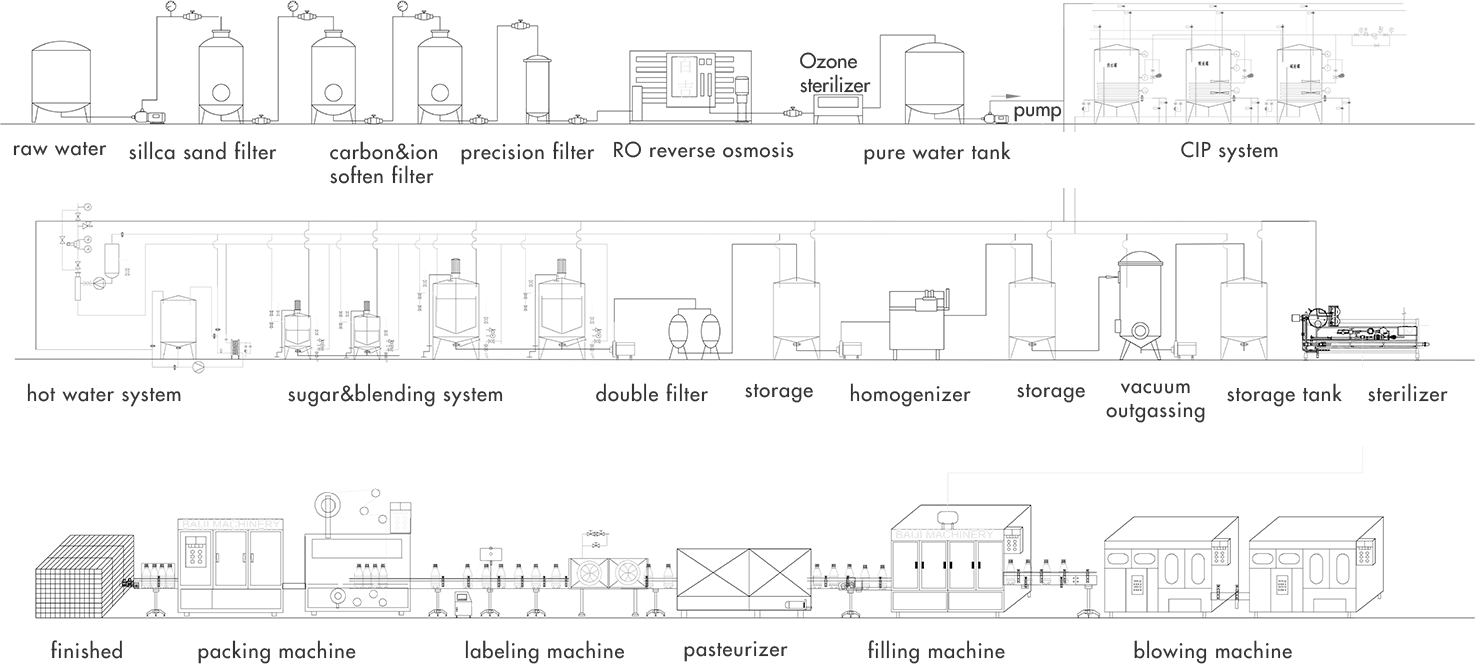

Complete fully automatic juice beverage production line mainly includes: Water treatment equipment, fruit juice beverage ingredients blending sterilization equipment, 3in1 hot filling machine, pasteurizer, blow drying equipment, labeling equipment, packaging equipment and CIP cleaning system.

![]() The machine is controlled by man-machine interface touch screen, PLC computer program control, frequency converter control.

The machine is controlled by man-machine interface touch screen, PLC computer program control, frequency converter control.

![]() For the different juice characteristics, we can provide different sterilizer before filling. Such as UHT sterilizer, pipe type sterilizer and plate type sterilizer.

For the different juice characteristics, we can provide different sterilizer before filling. Such as UHT sterilizer, pipe type sterilizer and plate type sterilizer.

![]() The juice blending system and sterilizing system will need heat to support working. So the boiler is essential to save the cost.

The juice blending system and sterilizing system will need heat to support working. So the boiler is essential to save the cost.

![]() The pressure-free conveying system can realize the bottle on the conveyor belt do not appear the phenomenon of squeezing each other.

The pressure-free conveying system can realize the bottle on the conveyor belt do not appear the phenomenon of squeezing each other.

Advanced water treatment technology.

Advanced water treatment technology.

Washing water can be recycled, can

Washing water can be recycled, can

save 80% of the washing water.

Stainless steel making machine

Stainless steel making machine

It is suitable for the separation of

It is suitable for the separation of

various fresh fruits and vegetables

All machine is made of stainless steel.

All machine is made of stainless steel.

It is the ideal machine for making jam, fruit juice and vegetable juice.

The working principle is that when the

The working principle is that when the

material is pushed by the screw, the volume of the screw cavity is reduced to form the

squeezing of the material.

It is specially used for filling 1 gallon to 5 gallon

It is specially used for filling 1 gallon to 5 gallon

bottled water.

It is specially used for filling 1 gallon to 5 gallon

It is specially used for filling 1 gallon to 5 gallon

bottled water.

It is specially used for filling 1 gallon to 5 gallon

It is specially used for filling 1 gallon to 5 gallon

bottled water.

The blending system includes sugar-melting pot, blending tank, double filter, vacuum degassing machine, homogenizer, uht sterilizer, storage tank and CIP online cleaning system.

The blending system includes sugar-melting pot, blending tank, double filter, vacuum degassing machine, homogenizer, uht sterilizer, storage tank and CIP online cleaning system.

It is mainly used for the preparation of fruit juice and sterilization, and for the preparation of fruit juice or mixed drinks before filling.

It is mainly used for the preparation of fruit juice and sterilization, and for the preparation of fruit juice or mixed drinks before filling.

The output ranges from 1 to 100 tons for customers to choose.

The output ranges from 1 to 100 tons for customers to choose.

Juice drinks generally use hot micro-negative pressure filling method.

Juice drinks generally use hot micro-negative pressure filling method.

The bottle has a certain high temperature resistance requirements, must withstand 85 degrees of filling without deformation, suggest to use high temperature blowing machine.

The bottle has a certain high temperature resistance requirements, must withstand 85 degrees of filling without deformation, suggest to use high temperature blowing machine.

The fruit juice filling machinery integrates the washing, hot filling and capping.

The fruit juice filling machinery integrates the washing, hot filling and capping.

Equipped with automatic circulation system, easy to low temperature material circulation heating and CIP cycle cleaning.

Equipped with automatic circulation system, easy to low temperature material circulation heating and CIP cycle cleaning.

Adopt screw transport the bottle, ensure the stability of the bottle feeding, 180° turn rinsing and dry, ensure the full cleanliness of the bottle.

Adopt screw transport the bottle, ensure the stability of the bottle feeding, 180° turn rinsing and dry, ensure the full cleanliness of the bottle.

Adopt the backflow filling mode, high precision, high speed filling valve, the liquid level is accurate without liquid loss.

Adopt the backflow filling mode, high precision, high speed filling valve, the liquid level is accurate without liquid loss.

2.The connection between the filling system and the sealing system is stable, and the material in the bottle has no external splash.

2.The connection between the filling system and the sealing system is stable, and the material in the bottle has no external splash.

Tunnel type pasteurization machine

Tunnel type pasteurization machine

Stainless steel making, have two kinds heating method, electric heating and steam heating.

Stainless steel making, have two kinds heating method, electric heating and steam heating.

PLC control system, auto water adding system, with anti-dry burning system.

PLC control system, auto water adding system, with anti-dry burning system.

Mostly used for products with granules or high viscosity beverage, products containing fiber and larger pulp granules, products of high acidity and products corrosive to the dead angle.

Mostly used for products with granules or high viscosity beverage, products containing fiber and larger pulp granules, products of high acidity and products corrosive to the dead angle.

It can be sterilized at high temperature and ultra-high temperature of 120-140 degrees.

It can be sterilized at high temperature and ultra-high temperature of 120-140 degrees.

Applicable to heating, sterilization, heat preservation and cooling etc. Requirements of fruit juice beverage.

Applicable to heating, sterilization, heat preservation and cooling etc. Requirements of fruit juice beverage.

Capacity from 0.5 to 50T/H. Sterilizing temperature from 85C to 95C. Heat preservation period is 15 to 3os.

Capacity from 0.5 to 50T/H. Sterilizing temperature from 85C to 95C. Heat preservation period is 15 to 3os.

According to the filling speed, the juice filling machine we provide 2000 bottles/hour, 4000 bottles/hour, 6000 bottles/hour, 10000 bottles/hour, 15000 bottles/hour and 24,000 bottles/hour machines.

| Model | RCGF16-12-6 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 | RCGF40-40-12 | RCGF50-50-15 | RCGF60-60-15 | RCGF72-72-18 | RCGF80-80-18 |

|---|---|---|---|---|---|---|---|---|---|

| Rinsing heads | 16 | 18 | 24 | 32 | 40 | 50 | 60 | 72 | 80 |

| Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 | 72 | 80 |

| Capping heads | 6 | 6 | 8 | 10 | 12 | 15 | 15 | 18 | 18 |

| Capacity(BPH) | 4000 | 5000 | 10000 | 12000 | 15000 | 18000 | 25000 | 28000 | 35000 |

| Motor power(KW) | 2.2 | 3.5 | 4.5 | 6.0 | 7.5 | 9.5 | 11.2 | 15.0 | 18.0 |

| Dimensions(mm) | 2300×1600 ×2500 | 2600×1920 ×2550 | 3100×2200 ×2800 | 3850×3000 ×2850 | 4850×3800 ×2750 | 5750×3550 ×2750 | 6500×5500 ×2750 | 6800×4800 ×2850 | 7200×5000 ×2850 |

| Weight(KG) | 2600 | 3650 | 4800 | 6800 | 8500 | 10000 | 12000 | 15000 | 18000 |