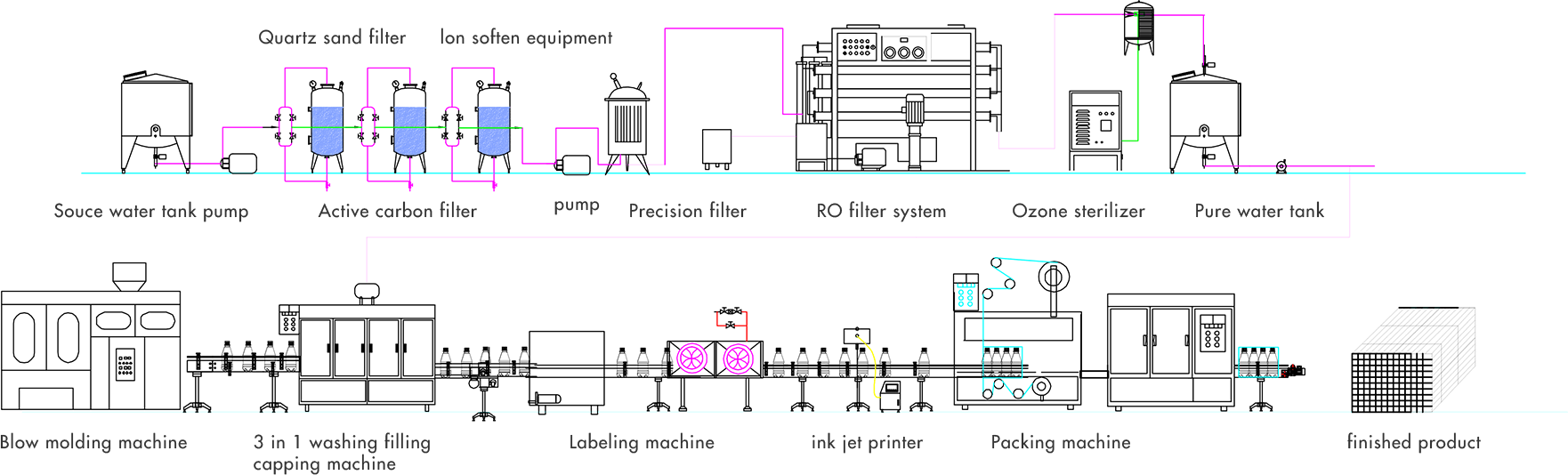

Complete bottled water filling production line is mainly composed of water treatment machine, bottle blow molding machine, filling machine and packaging machine.

What are the issues that our buyers need to consider to start the small bottled water filling business?

First, the source water quality inspection report. Second is the bottle volume, the approximate shape of the bottle, the filling speed requirements. Then the selection of labels, finished bottled water packaging, and the budget for the whole production line.

All the products are sold well.We devote ourselves to the development, research and production

of liquid food and beverage filling and packing industry .

![]() Pipes and valves are made of food grade stainless steel. Bearings are imported NSK or SKF.

Pipes and valves are made of food grade stainless steel. Bearings are imported NSK or SKF.

![]() The unique lubricating oil filling system can prevent the dry oil after the turbine equipment with the mechanical lubricating oil is consumed during the operation.

The unique lubricating oil filling system can prevent the dry oil after the turbine equipment with the mechanical lubricating oil is consumed during the operation.

![]() Adopt gravity filling principle, filling speed is fast, liquid level precision is high, ensure the filling quality.

Adopt gravity filling principle, filling speed is fast, liquid level precision is high, ensure the filling quality.

![]() It is equipped with stainless steel protective cover and plexiglass safety door. And equipped with maintenance hand-held switch and equipment emergency stop button.

It is equipped with stainless steel protective cover and plexiglass safety door. And equipped with maintenance hand-held switch and equipment emergency stop button.

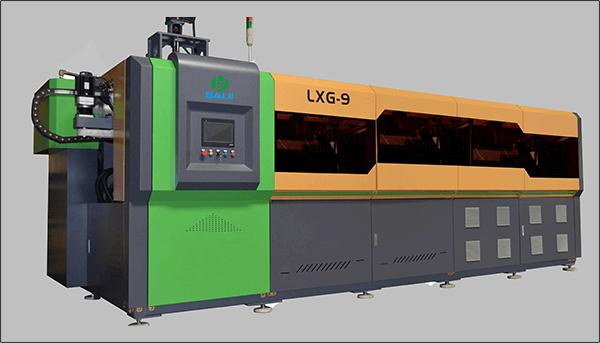

Stable infrared heating system and independent heat balance adjustment device, so that the preform heating temperature consistent

Stable infrared heating system and independent heat balance adjustment device, so that the preform heating temperature consistent

The specially designed secondary air blowing system can monitor the pressure change curve of each cavity bottle forming process in real time, and provide timely and accurate parameters for process adjustment, which is greatly convenient for operators to adjust process parameters and ensure the stability of bottle forming quality.

The specially designed secondary air blowing system can monitor the pressure change curve of each cavity bottle forming process in real time, and provide timely and accurate parameters for process adjustment, which is greatly convenient for operators to adjust process parameters and ensure the stability of bottle forming quality.

Mobile air-cooled type, simple structure, easy maintenance.

Mobile air-cooled type, simple structure, easy maintenance.

ultra-low speed, better smooth operation, no need to fix the foundation.

ultra-low speed, better smooth operation, no need to fix the foundation.

small vibration, low noise, long operation, economic and durable.

small vibration, low noise, long operation, economic and durable.

Suitable for PET water bottles, hot filling bottles, gaseous beverage bottles and edible oil bottles

Suitable for PET water bottles, hot filling bottles, gaseous beverage bottles and edible oil bottles

Bottle preform stretching can be segmented stretching, the first positioning of the bottle embryo, to ensure the verticality of the bottle preform when stretching, and then the second stretching.

Bottle preform stretching can be segmented stretching, the first positioning of the bottle embryo, to ensure the verticality of the bottle preform when stretching, and then the second stretching.

The filling machine integrates washing, filling and capping, suitable for filling 350, 500, 1L, 1.5L and other small bottles water.

The filling machine integrates washing, filling and capping, suitable for filling 350, 500, 1L, 1.5L and other small bottles water.

The part of pure water filling machine contact with water is made of food grade 304 stainless steel material, corrosion resistant and easy to clean.

The part of pure water filling machine contact with water is made of food grade 304 stainless steel material, corrosion resistant and easy to clean.

It has the advantages of small bottle wear, simple bottle shape replacement, accurate and stable transmission, scientific technological process and so on.

It has the advantages of small bottle wear, simple bottle shape replacement, accurate and stable transmission, scientific technological process and so on.

The production speed is up to 18000 bottles/hour, which can be connected to the high-speed filling line for production, greatly improving the production speed and saving the production cost.

The production speed is up to 18000 bottles/hour, which can be connected to the high-speed filling line for production, greatly improving the production speed and saving the production cost.

This machine is suitable for round, square, flat and cylindrical containers.

This machine is suitable for round, square, flat and cylindrical containers.

Only apply glue at both ends of the label to reduce the amount of glue used to save costs.

Only apply glue at both ends of the label to reduce the amount of glue used to save costs.

The labeling machine is suitable for ∮30 mm - ∮130 mm container

The labeling machine is suitable for ∮30 mm - ∮130 mm container

Full cover type stainless steel cover and aluminum alloy host machine make the operator more safe, full machine waterproof without rust.

Full cover type stainless steel cover and aluminum alloy host machine make the operator more safe, full machine waterproof without rust.

Labeling accuracy: ±1mm, Labeling speed: 0-150P /Min

Labeling accuracy: ±1mm, Labeling speed: 0-150P /Min

Automatic photoelectric, with no goods no labeling, no labeling automatic correction function.

Automatic photoelectric, with no goods no labeling, no labeling automatic correction function.

Image detection system, can realize the missing labeling, wrong labeling, repeat labeling crooked automatic prompt or eliminate.

Image detection system, can realize the missing labeling, wrong labeling, repeat labeling crooked automatic prompt or eliminate.

Designed and manufactured for high speed packaging requirements of bottled drinks (purified water, beverages, fruit juices, dairy products).

Designed and manufactured for high speed packaging requirements of bottled drinks (purified water, beverages, fruit juices, dairy products).

Automatically package the product in the forward delivery process, saving time and improving efficiency.

Automatically package the product in the forward delivery process, saving time and improving efficiency.

Programmable controller (PLC) control, can achieve automatic workflow.

Programmable controller (PLC) control, can achieve automatic workflow.

Arrange and combine products automatically according to customers' packing requirements.

Arrange and combine products automatically according to customers' packing requirements.

When packing, the equipment automatically opens and locates the top of the carton, so as to ensure smooth packing and no worries about jamming.

When packing, the equipment automatically opens and locates the top of the carton, so as to ensure smooth packing and no worries about jamming.

A wide range of application, can meet a variety of specifications of products packing.

A wide range of application, can meet a variety of specifications of products packing.

Small bottled water filling production line can also be called three in one filling machine, set washing, filling, capping in one monoblock unit, can be used to fill non-gas, small viscous liquid, such as pure water, mountain spring water, mineral water, soda water and so on. Based on 500ml PET bottles, the bottling water filling machine can produce 2,000 to 36,000 bottles per hour.

| Model | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 | CGF60-60-15 | CGF72-72-18 | CGF80-80-18 |

|---|---|---|---|---|---|---|---|---|---|

| Rinsing heads | 16 | 18 | 24 | 32 | 40 | 50 | 60 | 72 | 80 |

| Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 | 72 | 80 |

| Capping heads | 6 | 6 | 8 | 10 | 12 | 15 | 15 | 18 | 18 |

| Capacity(BPH) | 4000 | 6000 | 10000 | 12000 | 18000 | 22000 | 25000 | 28000 | 35000 |

| Motor power(KW) | 2.2 | 3.5 | 4.5 | 6.0 | 7.5 | 9.5 | 11.2 | 15.0 | 18.0 |

| Dimensions(mm) | 2400×1650 ×2500 | 2600×1920 ×2250 | 3100×2300 ×2800 | 3800×2800 ×2900 | 4600×2800 ×2900 | 5450×3300 ×2900 | 6500×4500 ×2900 | 6000×4800 ×2850 | 6500×5000 ×2850 |

| Weight(KG) | 2500 | 3500 | 4500 | 5600 | 8500 | 9800 | 12800 | 15000 | 18000 |