Carbonated drinks are very popular among people, especially among the young generation and children. Our company mainly processes three kinds of carbonated drink filling machine, There are glass bottle carbonated drink filling machine, plastic bottle carbonated drink filling machine and pop can carbonated drink filling machine.

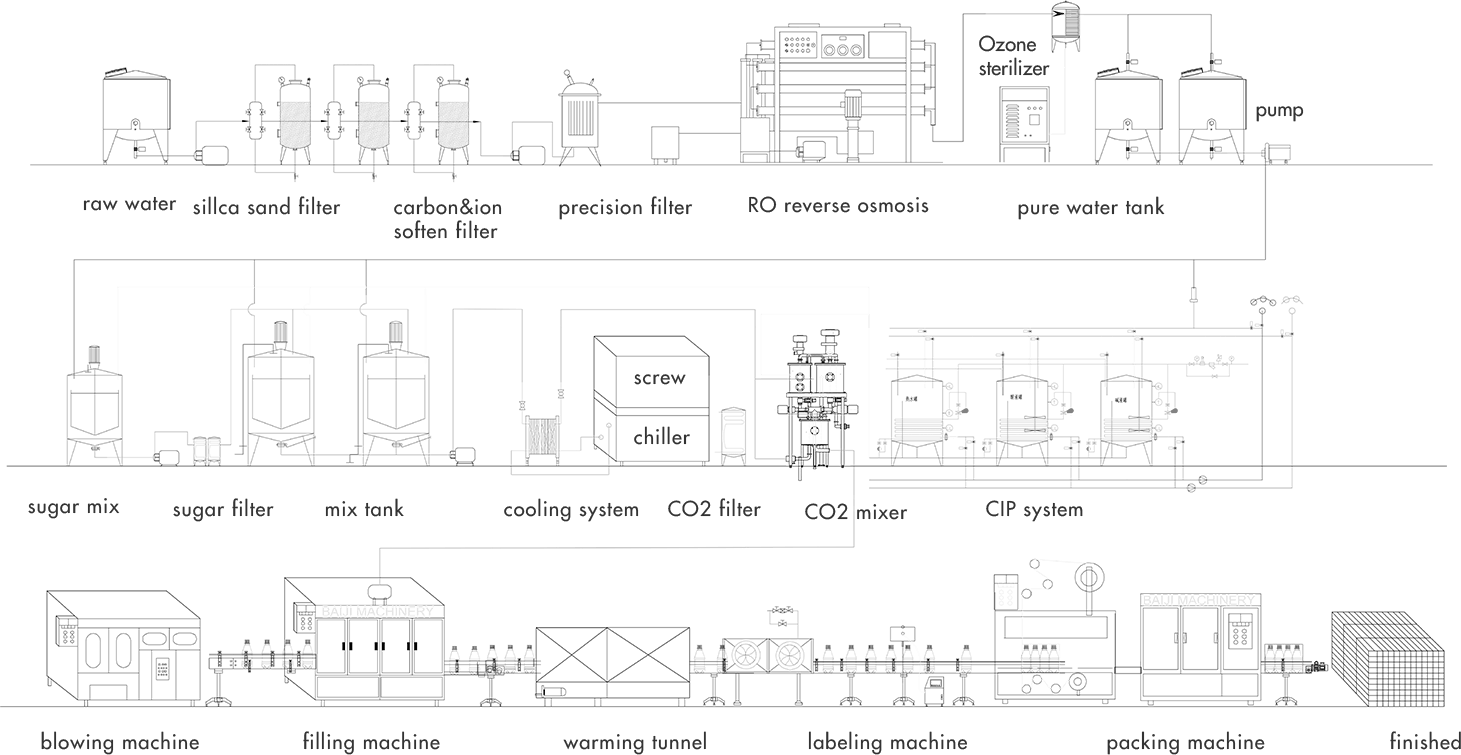

We can provide the floor layout according to customer’s requirements, the following one for reference is PET bottled soft drink layout design.

![]() The filling machine is designed and manufactured by using the principle of constant pressure filling, filling fast and sensitive, filling liquid level accuracy is high.

The filling machine is designed and manufactured by using the principle of constant pressure filling, filling fast and sensitive, filling liquid level accuracy is high.

![]() PET bottle transmission all adopts the bottleneck technology, changing the bottle shape no need adjust the height of the equipment, only need to replace the arc guide plate and a few star wheels can be realized.

PET bottle transmission all adopts the bottleneck technology, changing the bottle shape no need adjust the height of the equipment, only need to replace the arc guide plate and a few star wheels can be realized.

![]() Low temperature is very important for carbonated drink filling processing, special cooling system design will help co2 to mix better with liquid.

Low temperature is very important for carbonated drink filling processing, special cooling system design will help co2 to mix better with liquid.

![]() The soft drink mixer will equipped with static mixer and carbonator to make sure good taste.

The soft drink mixer will equipped with static mixer and carbonator to make sure good taste.

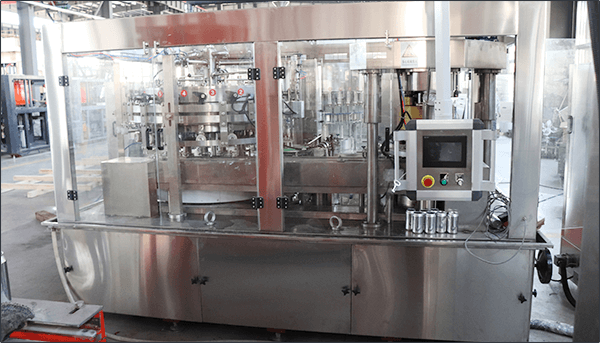

In the structure design of filling machine, we fully consider the characteristics of easy foaming of carbonated drinks.

In the structure design of filling machine, we fully consider the characteristics of easy foaming of carbonated drinks.

The parts in contact with the material are made of stainless steel, without process dead angle.

The parts in contact with the material are made of stainless steel, without process dead angle.

The machine adopts man-machine interface touch screen button, PLC computer control, equipped with missing cover, overload protection alarm device.

The machine adopts man-machine interface touch screen button, PLC computer control, equipped with missing cover, overload protection alarm device.

Monoblock filling and sealing machine , isobaric filling, filling valve specially designed for csd.

Monoblock filling and sealing machine , isobaric filling, filling valve specially designed for csd.

We use heavy duty bearings to extend the service life of the sealing roller.

We use heavy duty bearings to extend the service life of the sealing roller.

The stable filling and sealing capacity 60-400 cans per minute.

The stable filling and sealing capacity 60-400 cans per minute.

It is suitable for the production of 250ml, 500ml, 1L and other volumes of drinks containing carbon dioxide gas.

It is suitable for the production of 250ml, 500ml, 1L and other volumes of drinks containing carbon dioxide gas.

Provide modification parts according to different bottle type and volume of users.

Provide modification parts according to different bottle type and volume of users.

With automatic transmission lubrication system

With automatic transmission lubrication system

SUS304 stainless steel making. The processing system include sugar melting tank, syrup filter, double filter, mixing tanks.

SUS304 stainless steel making. The processing system include sugar melting tank, syrup filter, double filter, mixing tanks.

We will provide the hot water system, which is special designed to save the time of blending process.

We will provide the hot water system, which is special designed to save the time of blending process.

Suggest to use boiler to support the heat needed in blending process

Suggest to use boiler to support the heat needed in blending process

We installed a static mixer and carbonator to improve the taste of carbonated drink.

We installed a static mixer and carbonator to improve the taste of carbonated drink.

Adopt two times vacuum pumping to make sure carbonated drink mix well with co2.

Adopt two times vacuum pumping to make sure carbonated drink mix well with co2.

We can provide different model mixer to meet different gas percentage request of the customer. Such as two tanks mixer, three tanks mixer and five tanks mixer.

We can provide different model mixer to meet different gas percentage request of the customer. Such as two tanks mixer, three tanks mixer and five tanks mixer.

Co2 is more easy to mix with liquid in low temperature. So the chiller is important in the blending process.

Co2 is more easy to mix with liquid in low temperature. So the chiller is important in the blending process.

Screw type chiller adopt imported brand semi-closed asymmetric screw compressor, trouble-free operation of 100,000 hours.

Screw type chiller adopt imported brand semi-closed asymmetric screw compressor, trouble-free operation of 100,000 hours.

Environmental protection type R407C or R134A refrigerant is recommended

Environmental protection type R407C or R134A refrigerant is recommended

Low stacking type, international advanced design concept, more advanced and reasonable structure, more portable and stable movement, low power consumption.

Low stacking type, international advanced design concept, more advanced and reasonable structure, more portable and stable movement, low power consumption.

The adjustment of stacking mode is convenient and simple, and can be carried out on man-machine interface.

The adjustment of stacking mode is convenient and simple, and can be carried out on man-machine interface.

Adopts modular design, manual get on pallet or automatic get on pallet structure is optional, high cost performance; Targeted design of multiple safety protection functions.

Adopts modular design, manual get on pallet or automatic get on pallet structure is optional, high cost performance; Targeted design of multiple safety protection functions.

Provide customers with complete product formula, production process and raw material recommendation.

Provide customers with complete product formula, production process and raw material recommendation.

The main components of carbonated drinks are granulated sugar, high fructose corn syrup, water, food additives and carbon dioxide.

The main components of carbonated drinks are granulated sugar, high fructose corn syrup, water, food additives and carbon dioxide.

It is specially used for filling 1 gallon to 5 gallon

It is specially used for filling 1 gallon to 5 gallon

bottled water.

Plastic bottles carbonated beverage production line is suitable for the production of 350ml, 500ml, 1500ml gas drinks. The whole line include water treatment machine, bottle blowing machine, ingredients mixing machine, cooling equipment, filling machine, bottle warmer machine, labeling and film packing machine.

| Model | DCGF16-12-6 | DCGF18-18-6 | DCGF24-24-8 | DCGF32-32-10 | DCGF40-40-12 | DCGF50-50-15 | DCGF60-60-15 | DCGF72-72-18 | DCGF80-80-18 |

|---|---|---|---|---|---|---|---|---|---|

| Rinsing heads | 16 | 18 | 24 | 32 | 40 | 50 | 60 | 72 | 80 |

| Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 | 72 | 80 |

| Capping heads | 6 | 6 | 8 | 10 | 12 | 15 | 15 | 18 | 18 |

| Capacity(BPH) | 3000 | 5000 | 7000 | 10000 | 15000 | 20000 | 24000 | 30000 | 35000 |

| Motor power(KW) | 2.2 | 3.5 | 4.5 | 6.0 | 7.5 | 9.6 | 11.2 | 15.0 | 18.0 |

| Dimensions(mm) | 2300×1600 ×2500 | 2600×1920 ×2550 | 3100×2200 ×2800 | 3850×3000 ×2850 | 4850×3800 ×2750 | 5750×3550 ×2750 | 6500×5500 ×2750 | 6800×4800 ×2850 | 7200×5000 ×2850 |

| Weight(KG) | 2800 | 3650 | 4800 | 6800 | 8650 | 10500 | 12800 | 16000 | 20000 |