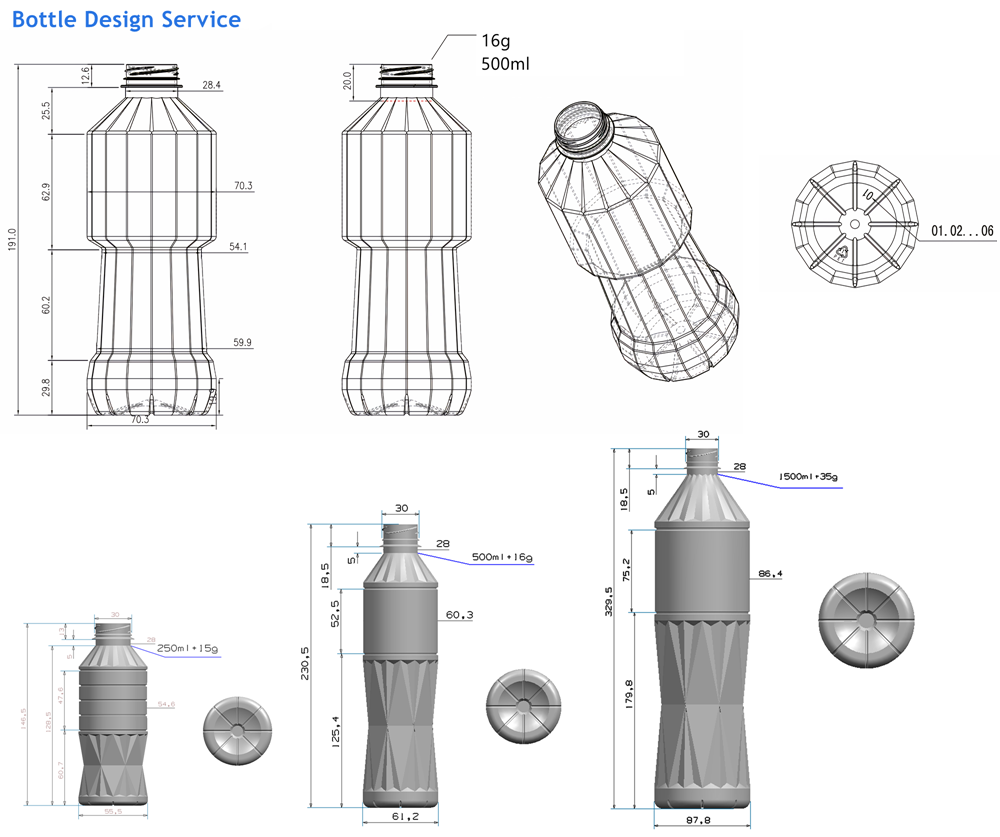

Semi automatic Bottle Blow Molding Machine is suitable for producing PET plastic containers and bottles from 10-2000ml. It iswidely used to produce the carbonated bottle ,mineral water,carbonated drink bottle, pesticide bottle oil bottle.

Features:

1, 0.2-2L PET bottle

2, Durable PLC micro computer controlling system controls time can be accurate to 0.01 seconds

3, Special recycling installation for high pressure air reduces the energy consumption.

4, The far-infrared heater uses a way of conversion self-rotating heating and the rail revolution makes the heating oven, quick and reliable.

5, Every heating lamp has independent temperature control device, to get ideal preform heating effect.

6, Particular pre-heater design makes preform close while heating. Change space, shorten heating tunnel and reduce energy consumption according to the size of bottle while blowing.

7, Simple installation and starting.

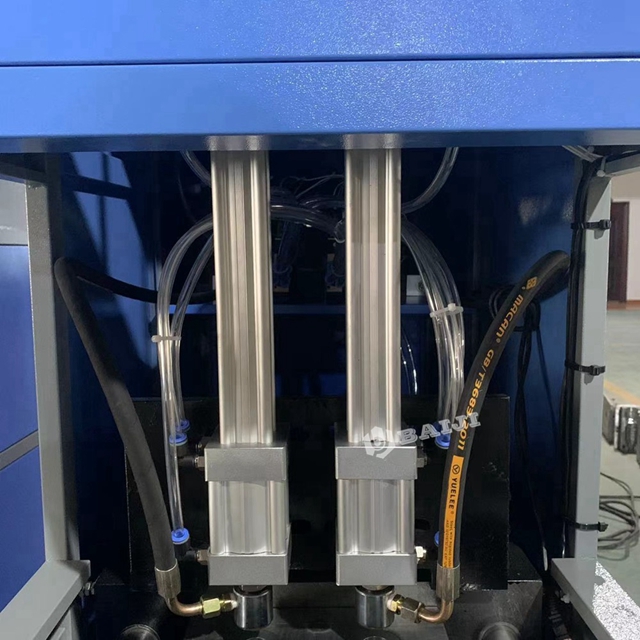

High Pressure Air Compressor -- Air Tank -- Air Fiter -- Air Dryer -- Low Pressure Air Compressor -- Air Fiter -- Semi Automatic Blow Moulding Machine -- Mould -- Water Chiller

| 2 cavities semi-automatic bottle blowing machine | ||

| Container | product material | PET |

| volume | 100ml - 2000ml | |

| theoretical output | 1400-1800pcs/h | |

| preform length | 15mm-350mm | |

| preform inner diameter | φ5-38mm | |

| Molding | max. mold plate dimension(L*W) | 350-380mm |

| max. mold thickness | 180mm | |

| clamping force | 45KN | |

| mold opening stroke | 160mm | |

| Machine weight and dimension | weight | 500kg |

| dimension(L*W*H) | 1600*600*1610mm | |