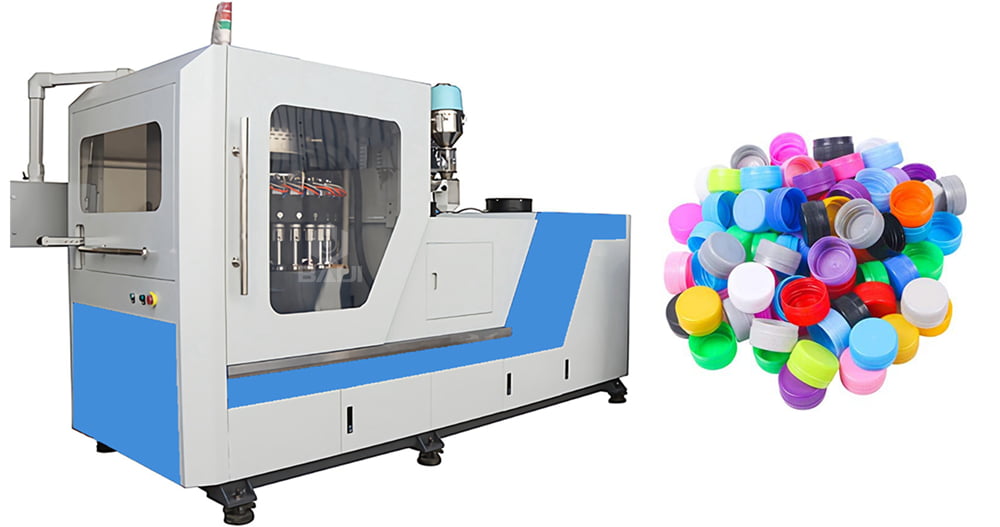

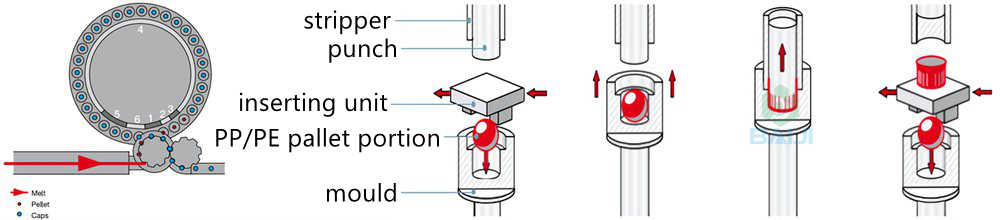

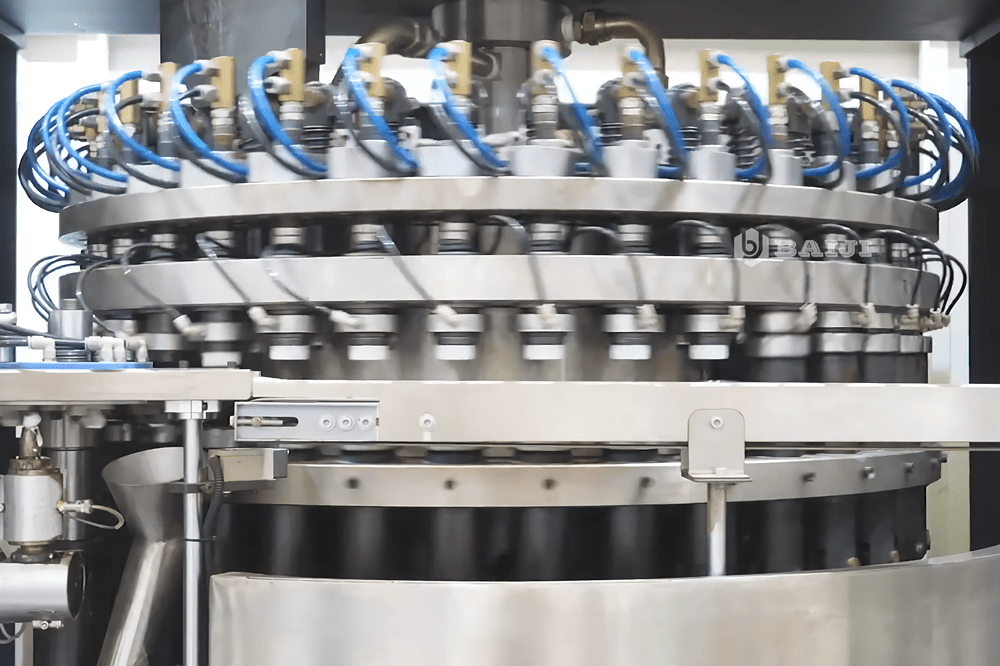

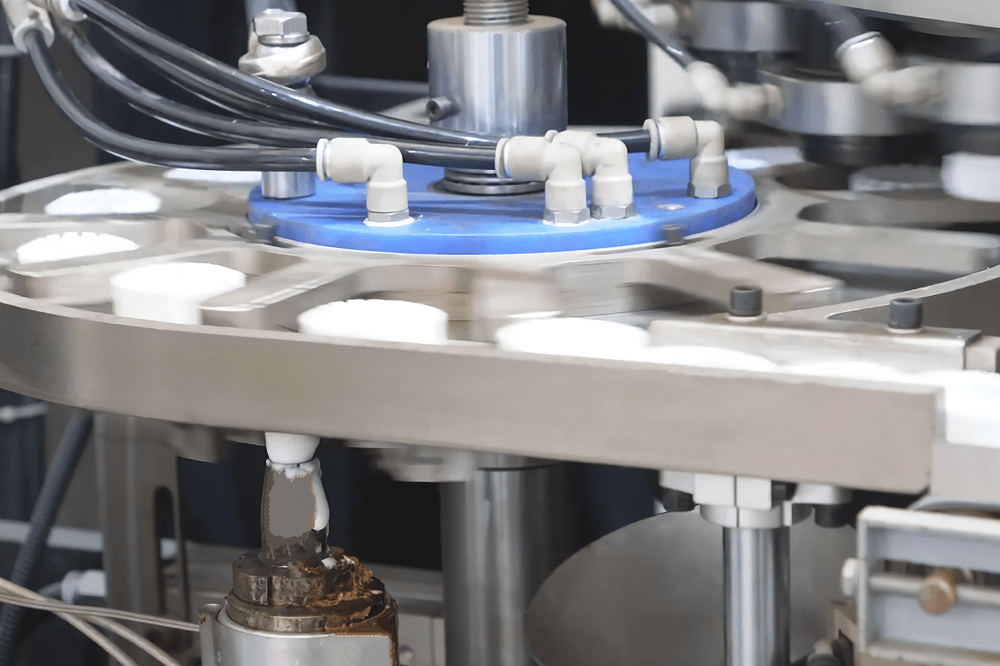

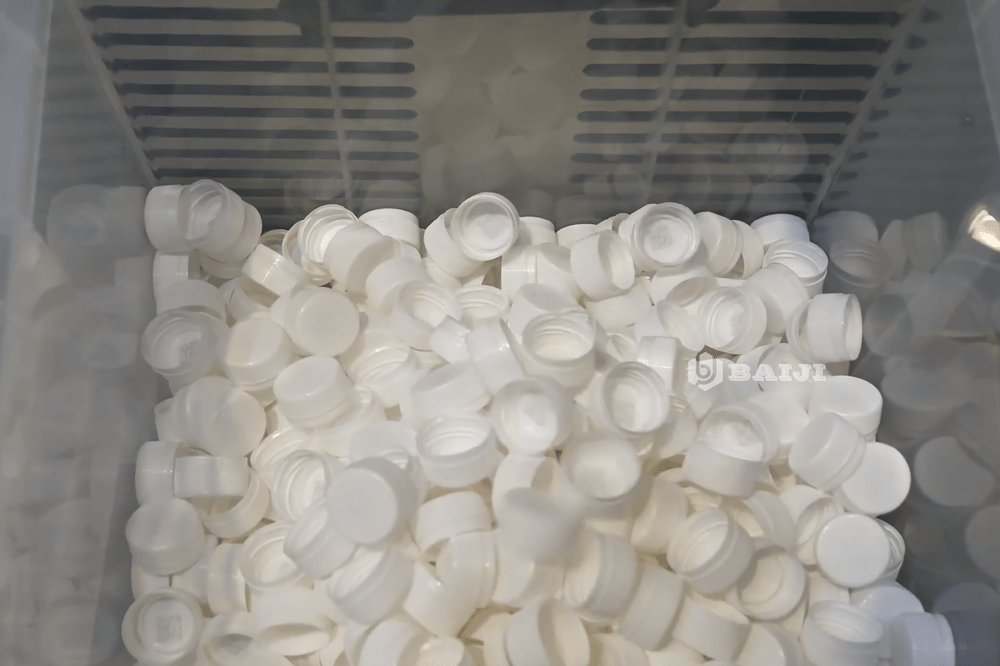

Cap compression molding machine is used to making the particles of plastic to the bottle caps of carbonated beverage and mineral water by high temperature plasticizing. When the plastic was out of the extruder, the Scraper plate will cutting the raw material putting them into the molding chamber uniformly.

Features:

Cap compression molding machine is used to making the particles of plastic to the bottle caps of carbonated beverage and mineral water by high temperature plasticizing. When the plastic was out of the extruder, the Scraper plate will cutting the raw material putting them into the molding chamber uniformly.

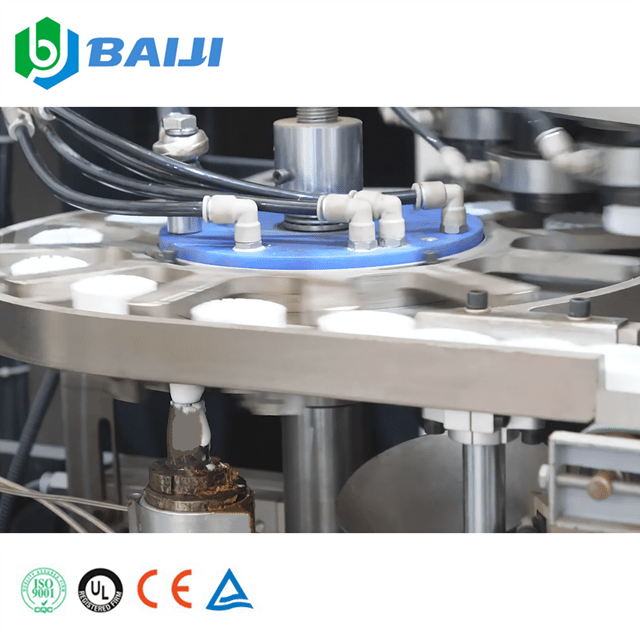

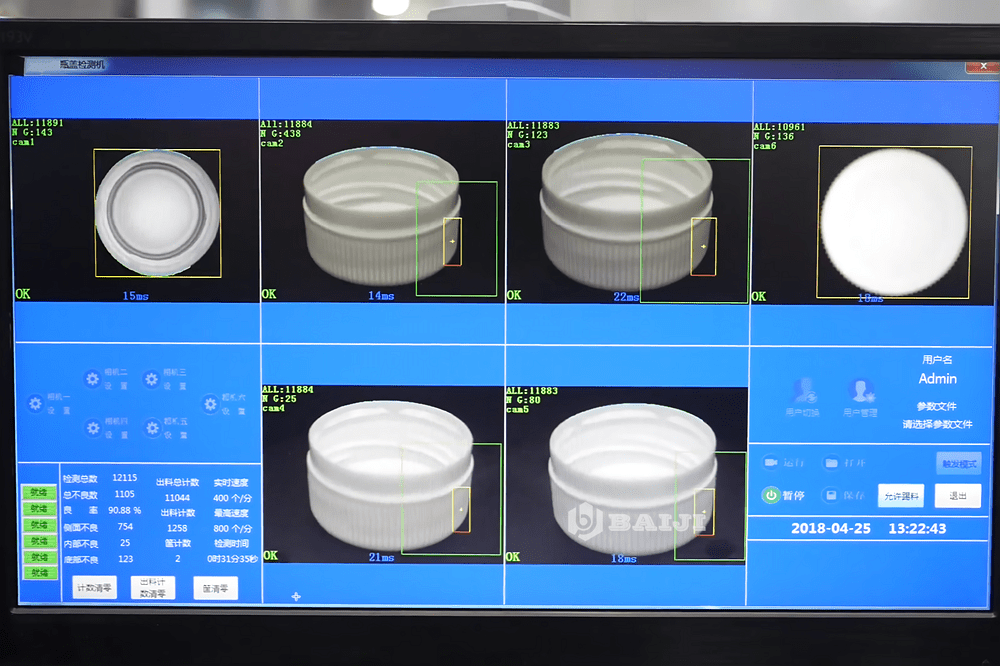

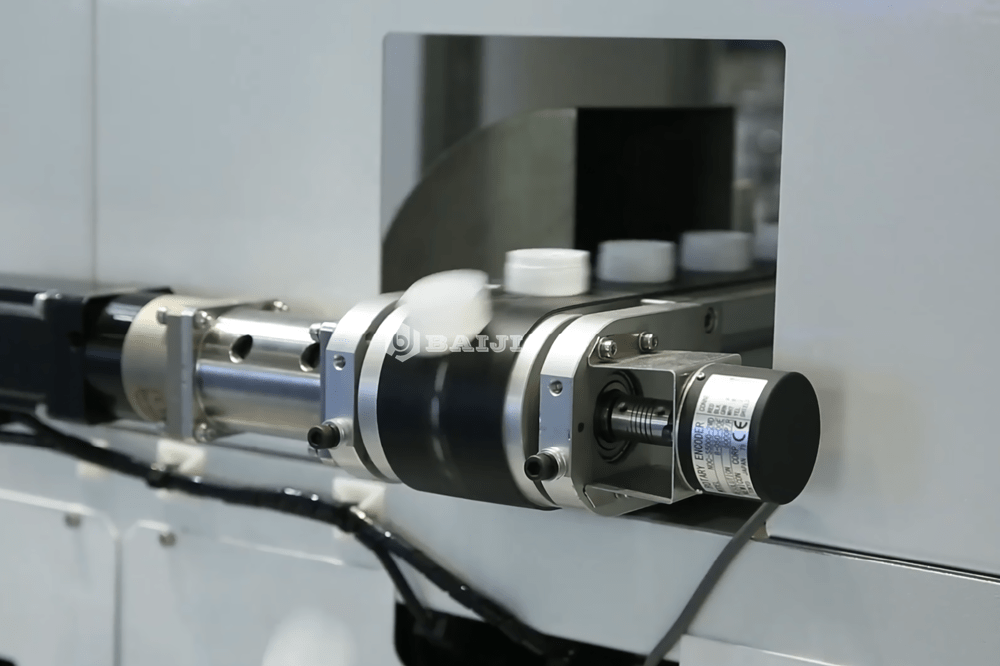

Cap inspection system

Cap inspection system will take bad cap automaticly, make sure good cap quality to your clients.

| Production capacity | 20000-24000 pcs/hour ( 30/25 29/25 cap ) |

| Cap diameter | 20 - 35 mm |

| Cap height | 10 - 30mm |

| Cap material | PP/HDPE |

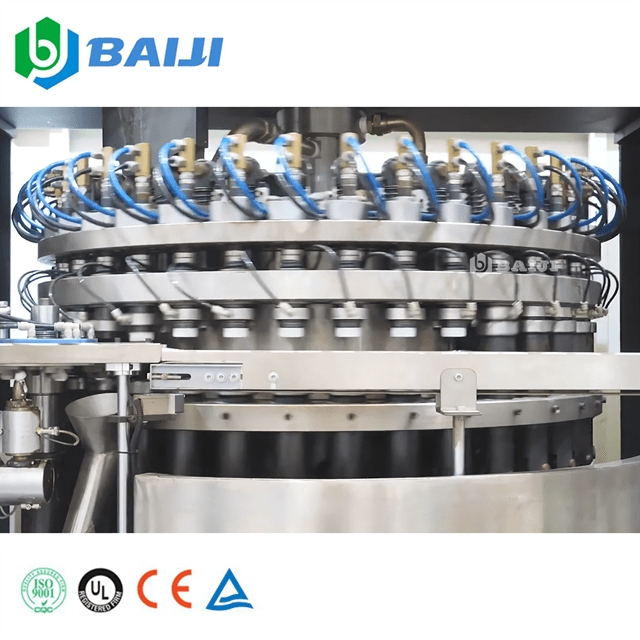

| Mold cavity No | 24 pcs |

| Machine voltage | 380 V / 50HZ / 3P , or by order |

| Machine electric power | 50kw |

| Air consumption | 1.4m³/h, 1.0Mpa |

| Machine dimension | 3800 * 1550 * 2100mm |

| Machine weight | 5800kg |