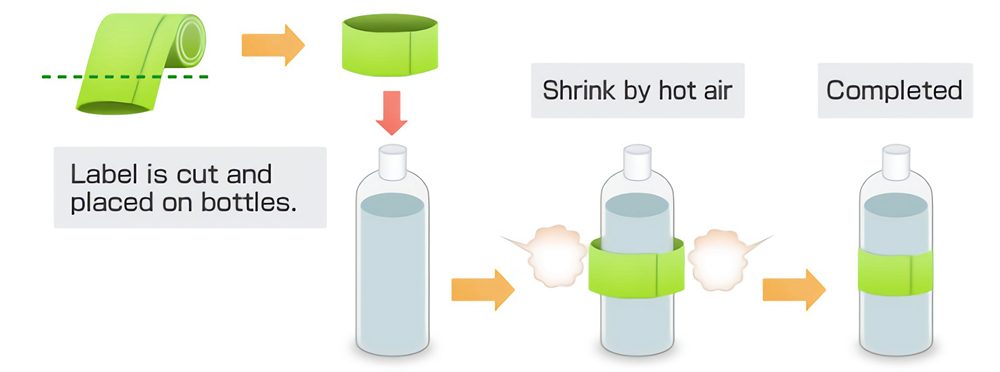

1, Sleeve shrink machine applies to food & beverage industries as fruit juice, tea, drink, dairy products pure water, condiments, beer and sports drink etc. 2, This bottle labeling machine is suitable for various kinds of bottle types:round bottle, square bottle, flat bottle etc. 3,Sleeve shrink machine not only has a highly precise position for casting label, but also withstand the perfect shape of the bottle after shrinkage.

Features:

The shrink sleeve labeling machine is equipped with SUS304 cover and aluminumalloy structure. It is suitable for the round bottle, square bottle, oval bottle, flat bottle, curve bottle, bottle mouth and bottle body. Blade replacement is easy and cost is low. Servo motor controls cutting operation to last the blade service time and make label more accurate. It owns automatic computer control, automatic detection, automatic positioning, fast label replacement, accurate label cutting, colour HMI with English and other characteristic. This labeling machine is easy to operate and no worker needed. It equipped with alarm device.

Shrink sleeve labeling machine

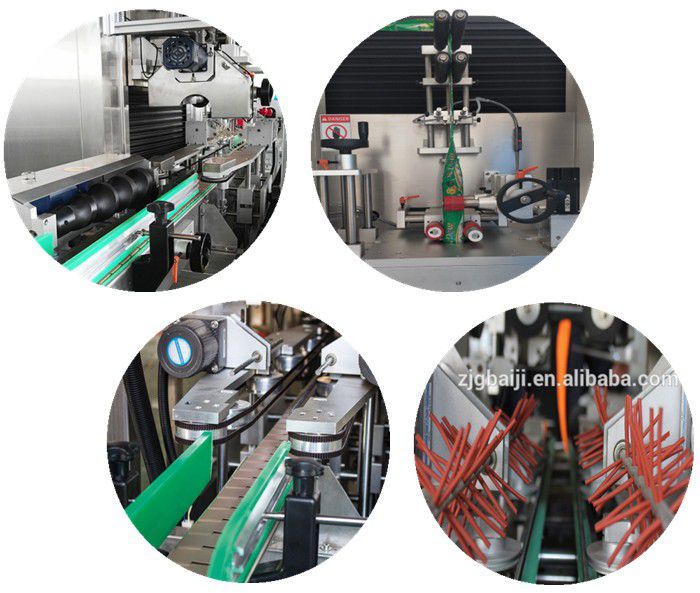

1, the machine is made of stainless steel and high quality of aluminum alloy, the reasonable, intact frame, it is easy to adjust.

2, the applicable bottle is the machine square bottle and round bottle.

3, without tools, the driven machinery can be adjusted to meet different bottle size.

4, adopting panasonic servo motor made in Japan and sensitive photo electricity, to ensure the precision of cutting label.

5, stainless steel electric controller, adopting Mitsubishi PLC made in Japan.

Shrink tunnel

1, suitable for different and irregular round bottle, square bottle and flat bottle etc.

2, new-style steam shrinking oven is easy to adjust and maintain.

3, the whole machine is made of stainless steel with heat preservation.

4, complies with the international safety standard.

Steam generator

1, fully automatic electrical heating generator by high pressure potential vortex pump made of cooper with short water-supply time and durable service.

2, a floating ball for liquid level is fixed in the water tank to automatically control the water inlet.

3, after connecting the water supply and power supply for 5 minutes or so, it can output the steam continuously with a high level of working efficiency.

| Model | TB-150B | TB-250B |

| Input power | 1.5kw | 3kw |

| Input voltage | 3 phase, 380/220V, 50hz | |

| Production efficiency | 150 bottle/min | 250 bottle/min |

| Size of host machine (L*W*H) | 2100*850*2000mm | |

| Applicable diameter of bottle body | 28-125mm | |

| Applicable length of label | 30-250mm | |

| Applicable thickness of label | 0.03-0.13mm | |