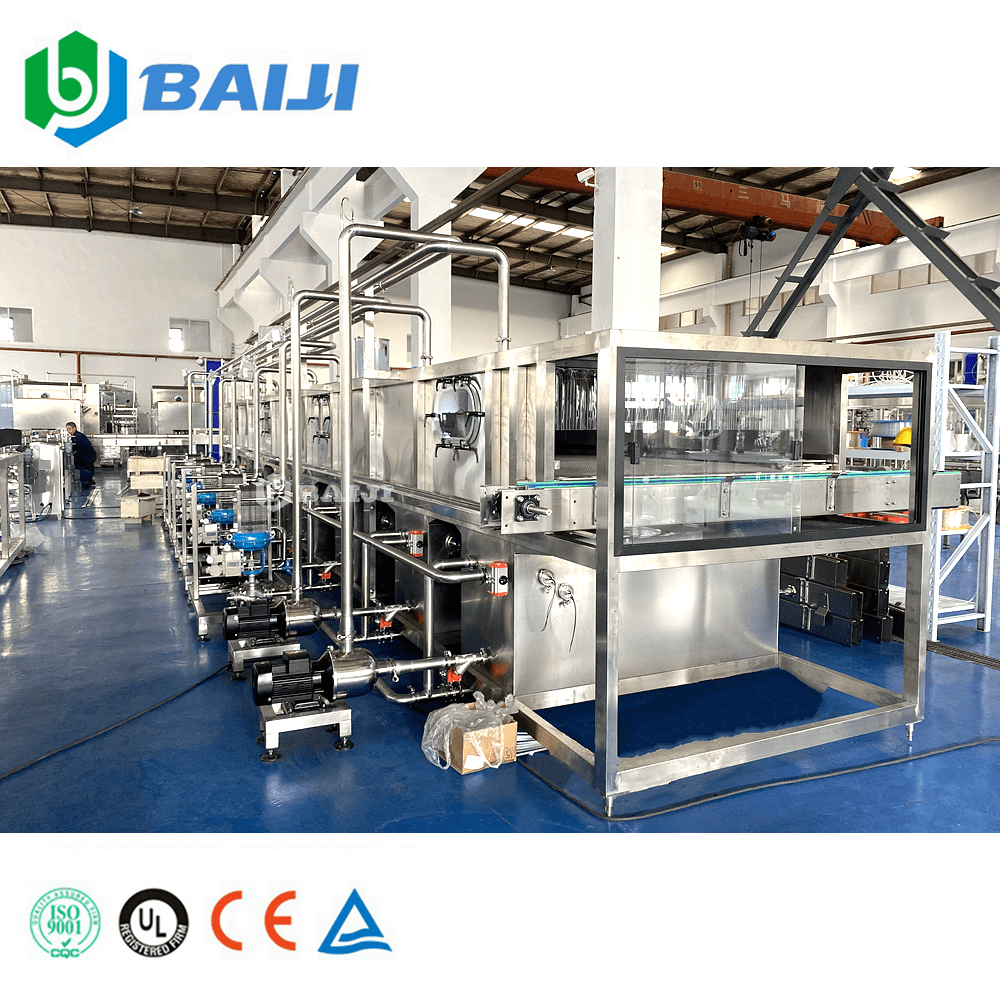

This series of filling machines are used in production of PET bottled carbonated beverage, such as carbonated water, sprite and so on.This series of products are the integrated rinsing, filling and capping machine, suitable for producing various PET bottled carbonated beverage.Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as JapanX’s Mitsubishi France Schneider, Siemens.

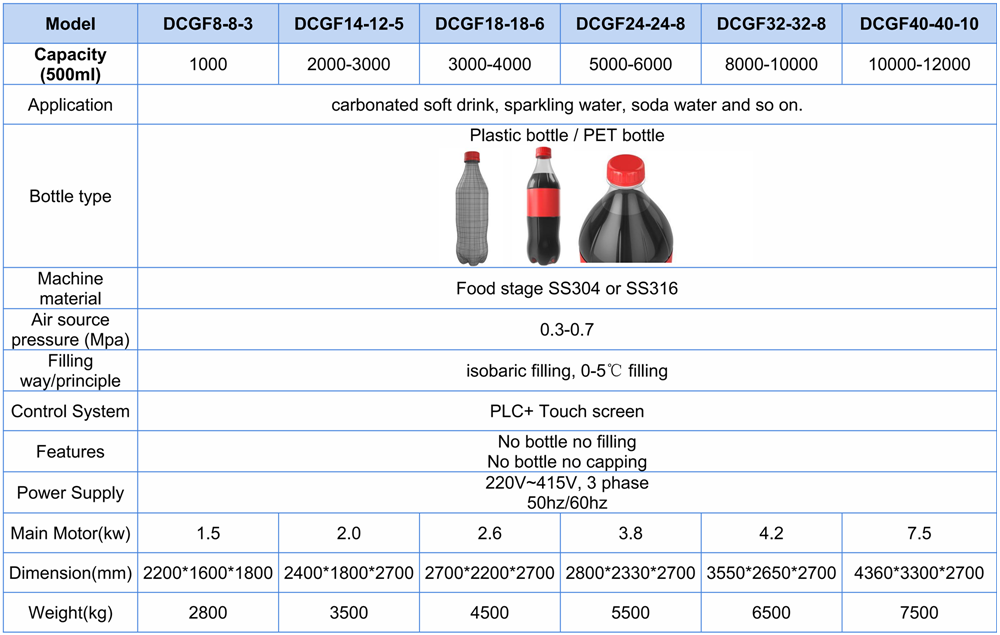

DCGF series of carbonated soft drink filling machine, it is a monoblock unit, integrated with washing filling and capping machine. It is suitable for all kinds of carbonated beverage, such as carbonated soft drink, sparkling water, soda water and so on.

Low temperature enhances solubility of CO2. The filling temperature of carbonated beverage is 0~5°C. Before mixing with CO2, the mixture temperature of water and syrup is at 60℃. We need to use a refrigeration unit to reduce the mixture temperature to less than 4℃.

|  |

Carbonated soft drink mixer

It can improve the proportion of water, syrup and carbon dioxide. It is used in carbonated beverage production line and sparkling wine. It is used to cooling the water before mixing which is connected with the mixer.

PET bottle warmer

It is used to warm the carbonated drink bottle after low temperature filling, as the carbonated drink after filling, its bottle touch the outside air, it will has a lot small water drops outside, use this machine will warmer it to normal temperature, and after dryer machine, it will be good for labeling.

Automatic OPP hot glue labeling machine

Infeed bottle → pre-position → label cutting → gluing → labeling→ label by press out → finish

Automatic PE film wrapping machine

You can decide 24 bottles one package, 12 bottles one package, etc. It is changeable.

bottle blowing machine |  air conveyor |

water treatment system |  blow dryer |

date printer |

|

SEW motor |  convey lubrication |

automatic lubrication |  oil can be to the main bearing |