The principle that the intensity of rays varies with the position of the material surface to control the capacity of liquid material to be tested and filled because of its non-contact measurement. It solves the problem that the conventional weighing method can not measure the volume of liquid material on production line.

Features:

The principle that the intensity of rays varies with the position of the material surface to control the capacity of liquid material to be tested and filled because of its non-contact measurement.

It solves the problem that the conventional weighing method can not measure the volume of liquid material on production line.

So it is widely used in food, medicine and chemical industry. whether bottle or can on-line automatic control of liquid material production line.

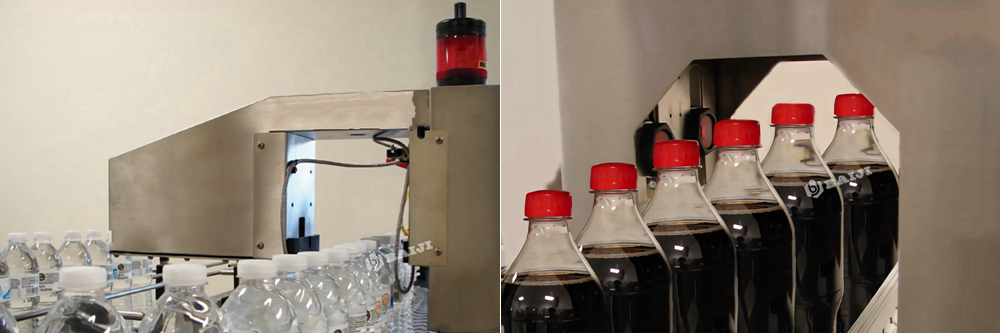

Application: on-line detection of liquid level, such as cans, PET bottles, glass bottles, etc.

| Application | Beer, carbonated beverage, soft drink, cold coffee, herbal tea, fruit juice, etc. |

| Suitable package | Aluminum can, Tin can, PET bottle and glass bottle |

| Detect diameter | 20mm-100mm |

| Production speed | 300-600 cans/minute |

| Weight | 100kg |

| Dimension | 1300mm×800mm×500mm |