RCGF40-40-12, 15000 bottles per hour, 200ml~2000ml PET bottle, integrated with washing filling and capping machine

RCGF series of juice filling machine, it is used for bottling organic fruit juice and concentrate juice, fruit juice with additives, juice with pulp, coffee, flavoured water and so on.

It is mainly designed for hot temperature liquid(85-90℃). If temperature is lower than setting value, filling valves will stop, beverage return to UHT.

Water treatment system

Raw water tank + Raw water pump

Quartz sand filter + Active carbon filter + Sodium ion exchanger + Precision filter

RO Reverse Osmosis ( one stage )

UV sterilizer / ozone generator

Finished water tank + Pure water pump

Juice blending system

Sugar melting tank → syrup filter → blending tank → double filter → storage tank → homogenizer → storage tank → vacuum degasser → storage tank → plate type sterilization

Automatic PET bottle blowing machine

It is suitable for producing PET plastic bottles in all shapes. It is widely used to produce the pure water bottle, mineral water bottle, carbonated drink bottle, juice hot fill bottle, oil bottle and so on.

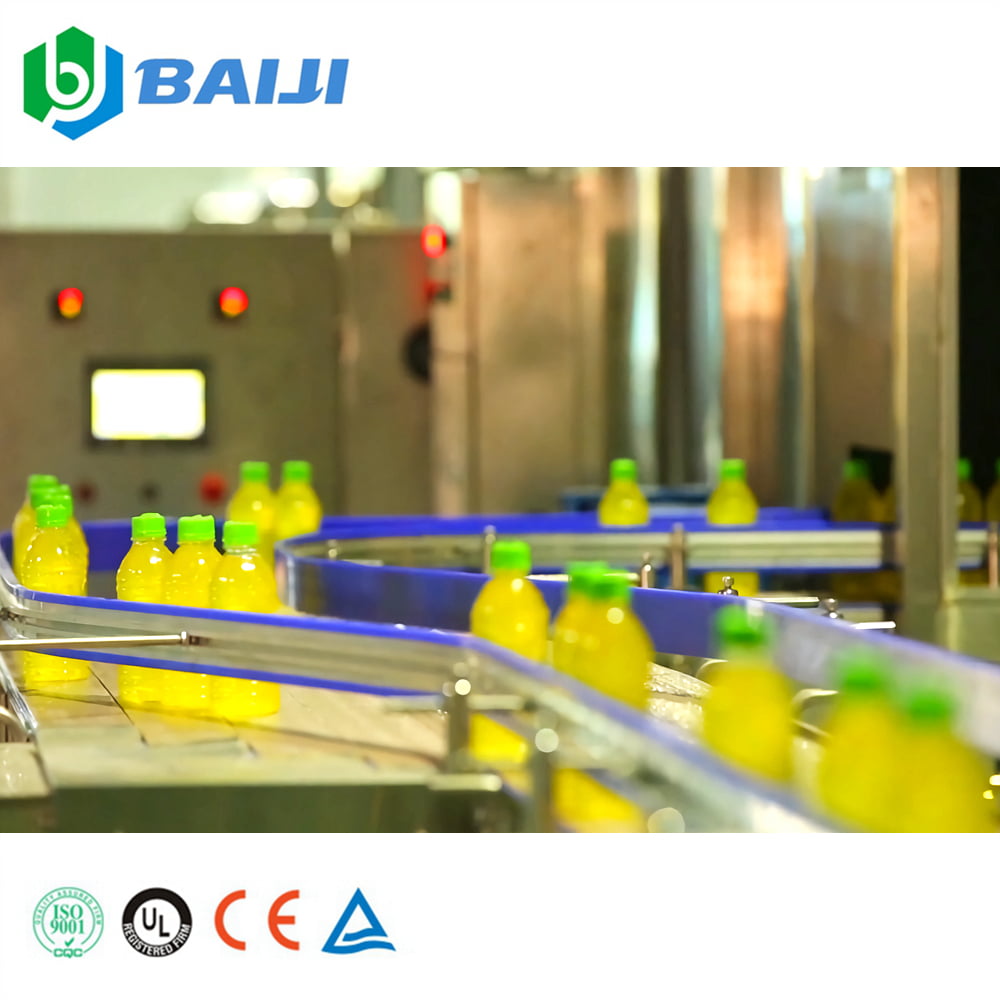

Automatic Juice Bottle Washing Filling Capping 3 in 1 Machine ( Monoblock Type )

It can work for different size bottle from 200ml to 2000ml, but do make sure the same cap. Actually, we can provide different models filling unit according to your speed needs. Min. 2000-3000bph, Max. 24000bph.

Pasteurization

It is usually used after fruit juice beverage finished hot filling and sealing, when enter the spray tunnel, the water with the function of high-pressure pump, uniformly spray on the bottle body. The bottles move slowly in the chain, when they are out the tunnel, they can reach the normal temperature, then achieve the purpose of cooling. This machine can also be used for secondary sterilization for fruit juice.

Automatic OPP hot melt labeling machine

Infeed bottle → pre-position → label cutting → gluing → labeling → label by press out → finish

Automatic PE film wrapping machine

To pack several bottles into one package, make it easier for delivery.

You can have different group style, 24 bottles one package, 12 bottles one package, etc. It is changeable.

inverted bottle sterilizer |  date printer |

SEW motor |  convey lubrication |

automatic lubrication |  oil can be to the main bearing |

Baiji machinery can help you design factory layout, bottle shape, label, etc.