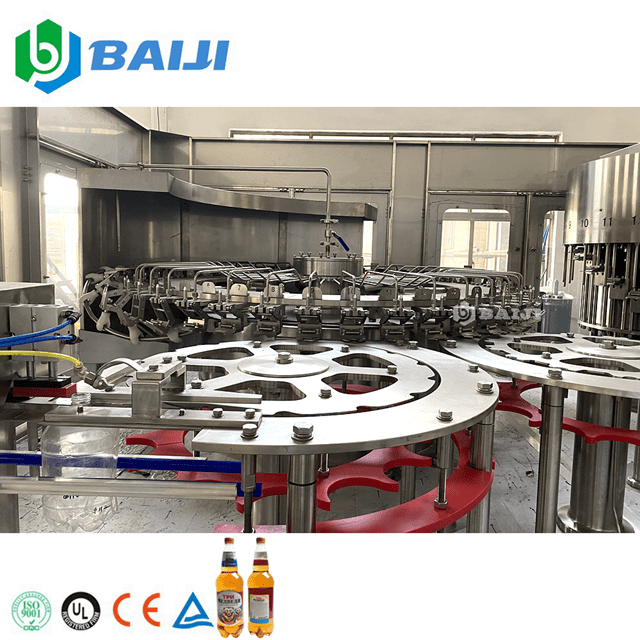

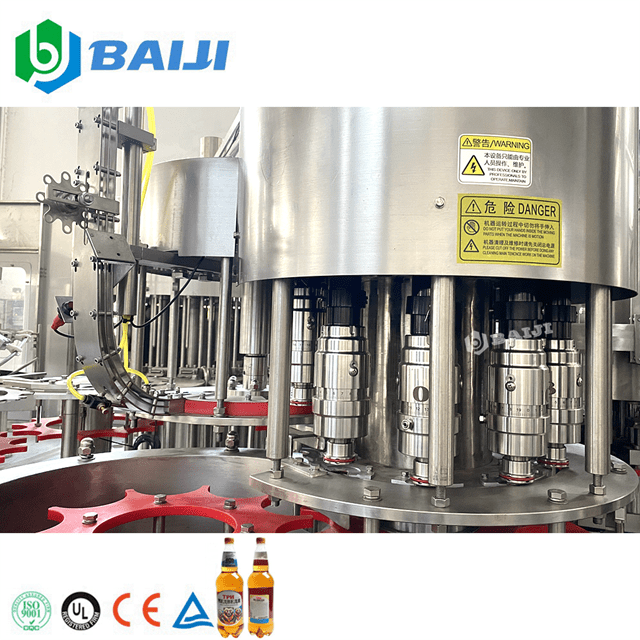

Beer Filling Machine adopts advanced 'Secondary Vacuum and High Pressure Bubble Injection' technology to decrease oxygen content and improve the taste of beer; with precise pressure control and automatic defective bottle detection function, final product of Beer Filling Machine realizes perfect quality at all times.

We supply complete solution for PET bottled beer production line, including beer filling machine ( rinsing, CO2 replacement system, beer filling, capping 4 in 1 )

|  |

|  |

| Model | 24-18-24-10 | 40-24-40-10 | 60-32-60-15 |

| Capacity ( bottles per hour ) | 5000 | 8000 | 12000 |

| Application | beer, craft beer, carbonated beverage and so on. | ||

| Suitable bottle | plastic PET bottle | ||

| Machine material | Food stage SS304 or SS316 | ||

| Control system | PLC+Touch screen | ||

| Features | No bottle no filling No bottle no capping | ||

The complete filling process will be as below:

①, The replacement valve is linking with air drum, CO2 inside air drum enter bottles via replacement valve. The gas inside bottle now is mixing with CO2 and air.

②, Air exhausting valve is opened via cam to exhaust the mixed gas.

③, Refill CO2 into bottle again.

④, Operation valve open, after the pressure between cylinder and bottle is equal, the filling process starts, when the filling level reach air returning pipe, filling stops, filling valves closed.

⑤, After filling process finishing, before filling valves leaving bottles, air exhausting valve exhaust extra gas, then filling valves leave bottle neck, filling process finishes.

Automatic PET bottle blowing machine

It is suitable for producing PET plastic bottles in all shapes. It is widely used to produce the pure water bottle, mineral water bottle, carbonated drink bottle, juice hot fill bottle, oil bottle and so on.

|  |

Beer brewing system

Beer sterilizer

8 temperature sections:

1, preheating: 26℃, 41℃, 50℃

2, sterilization: 68℃ ( heating ), 63℃ ( insulation )

3, cooling: 48℃, 39℃, 28℃

Automatic adhesive stick labeling machine

Automatic carton box packing machine

|  |

Handle ring insert lifting inserting pressing machine

pipe |  CIP system |

date printer |  conveyor system |

SEW motor |  convey lubrication |

automatic lubrication |  oil can be to the main bearing |