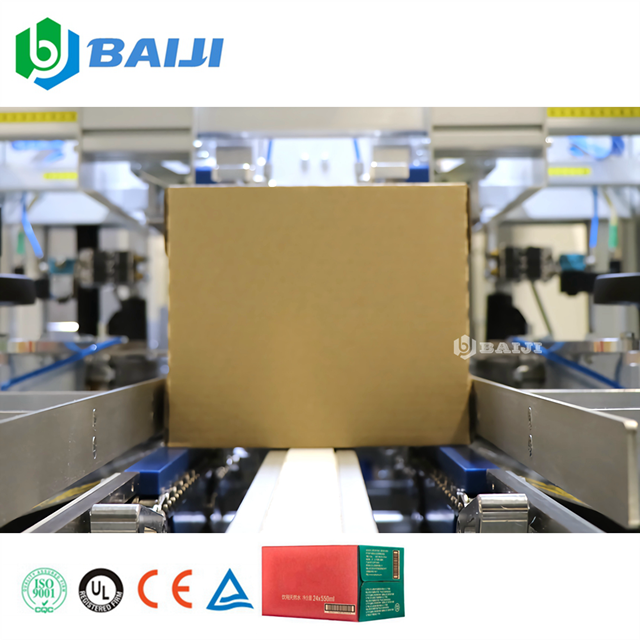

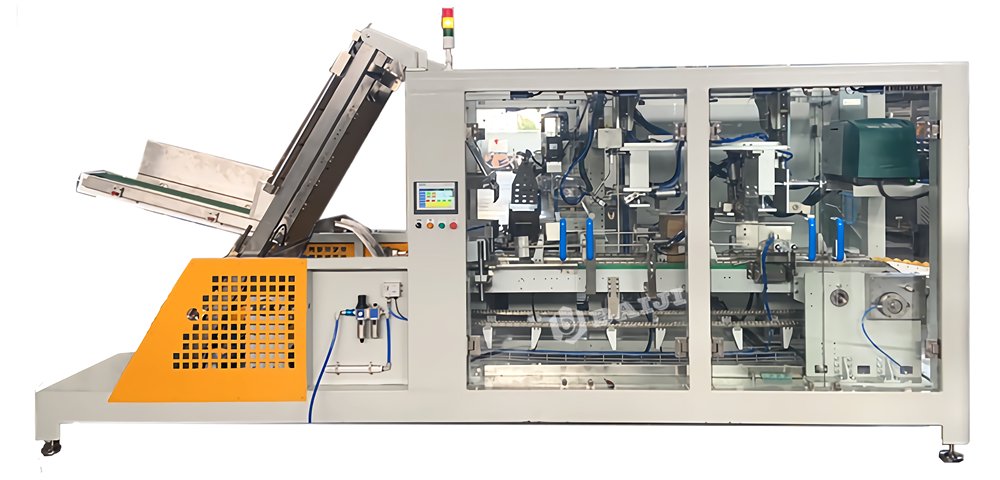

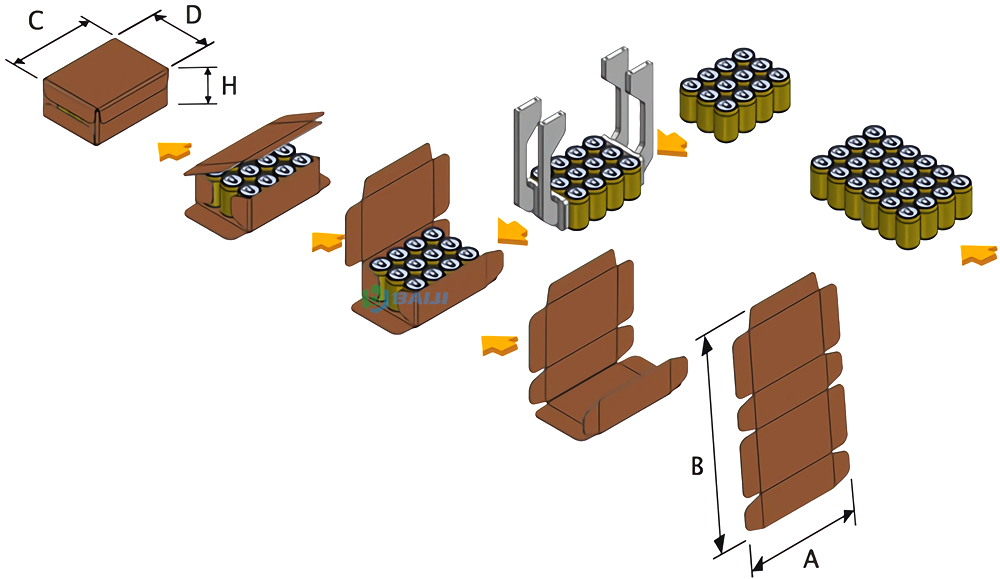

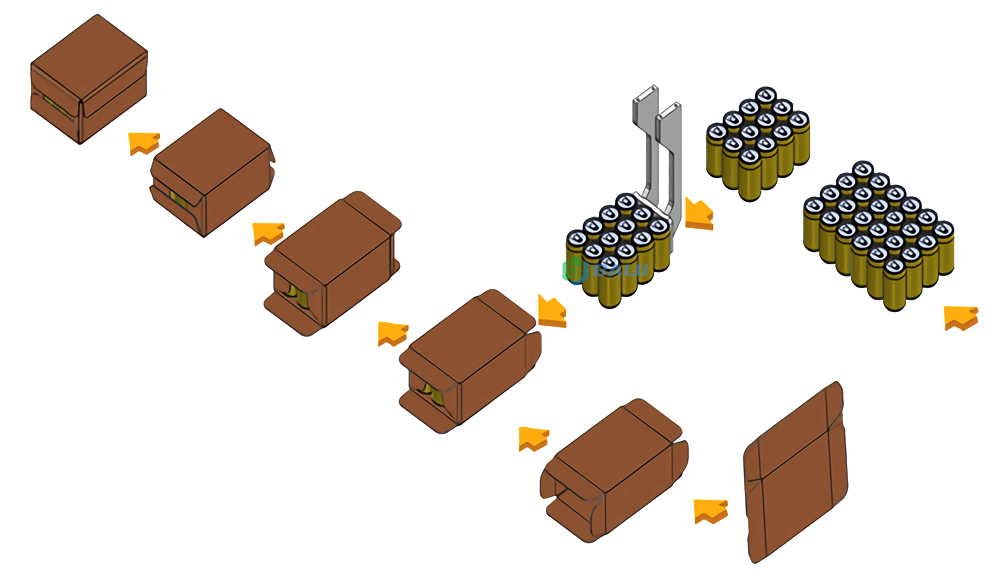

It is suitable for automatic Tetra Pak products packaging into carton cases. Tetra products are coming one by one from conveyor and by a multi-lane dispenser, the products are grouped and formed the A*B pattern format. Meanwhile, the carton supplying unit sucks the cardboard and forms the carton box, delivers it to the product loading station and finally products are pushed to the carton, get ready for the next carton sealing process by hot melt glue or by adhesive tape.

Features:

It is suitable for automatic Tetra Pak products packaging into carton cases. Tetra products are coming one by one from conveyor and by a multi-lane dispenser, the products are grouped and formed the A*B pattern format. Meanwhile, the carton supplying unit sucks the cardboard and forms the carton box, delivers it to the product loading station and finally products are pushed to the carton, get ready for the next carton sealing process by hot melt glue or by adhesive tape.

| Dimension | L17250mm*W1800mm*H2700mm |

| Shrinkage tunnel dimension | L2500mm*W700mm*H450mm |

| Max package dimension | W=180-300,L=240-420 |

Packing speed | 30-35pcs/min |

| Transfer belt width | 610mm |

| Voltage / Power | 3Phase 5Line 380V 70kW |

| Air pressure | 0.6-0.8Mpa |

| Air consumption | 150NL/min |

| Weight | 5500Kg |

| Product keywords | Side push carton box wrapping packing machine Wrapping pack machine Shrink Wrapper With cardboard pad PET glass bottle shrink wrapping machine Aluminum can / Tin can shrink wrapping machine |