Pure bottle water production line working principle: the conveyor belt will cleaning bottle into the bottle feeding wheel and guide positioning by the positioning thumbwheel organization order. When the bottle get into after her agency in institutions under the control of CAM, bottle to bottle up, top open after filling valve, liquid under the action of atmospheric pressure, automatic into the bottle, after the completion of the bottle in the control of the CAM down to the height of bottle, by dialing wheel will fill good bottle to the conveying screw cap machine.

The bottle is passed through the wind, and then sent to the three-to-one machine by the dial star wheel. Tuming machine back wheel is equipped with bottles clamp, clamp of bottle bottle along a guide rail turn 180 °, the bottle down. In the specific area of the bottle washer, flush the bottle with the nozzle and flush the inner wall of the bottle. After the bottle is washed and drained, the bottle is rotated 180 times along the guide rail to make the bottle mouth up. After washing, the bottle is exported by the bottle star wheel and sent to the filling machine. The bottle that enters the filling machine is lodged by the bottle neck and the bottle is raised under the action of the CAM, then the filling valve is opened by the mouth of the bottle. Filling adopts gravity filling method.

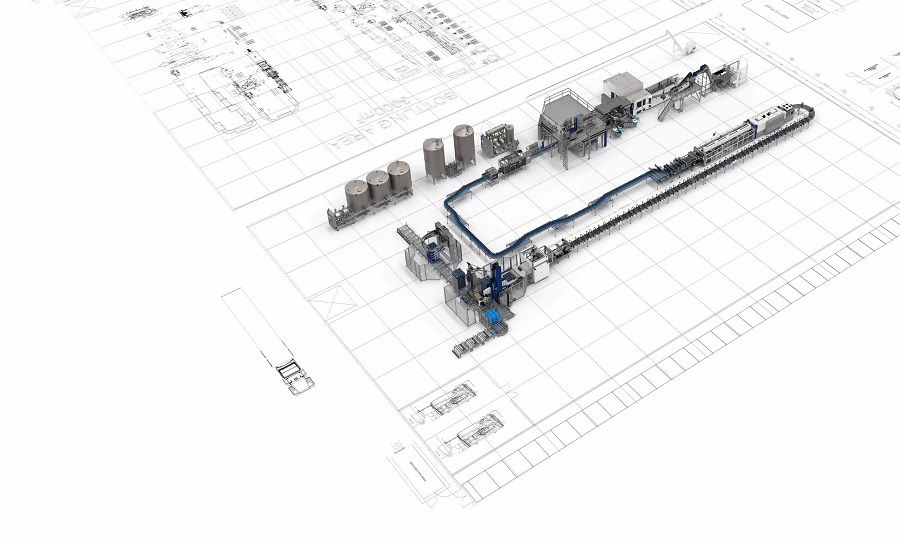

Bottle blowing equipment: mainly used for embryo bottle blowing into the bottle, bottle embryo into oven heated in the first place, through the tubes provide heat source, bottle embryo in the process of heating, the revolution and rotation, guarantee the bottle embryo surface evenly heat, have certain plastic bottle embryo, after entering the bottle mold, with the filtered high pressure gas bottle blowing into the bottle embryo.

Bottled pure water production line has washing bottle, filling and sealing parts. The washing machine adopts the multi-channel washing liquid injection and disinfect injection to achieve the purpose of washing and disinfection. The disinfectant can be recycled. Sealing machine can automatically seal. The series production line can be automatic cleaning, disinfection, filling, gland, count and output, with complete functions, novel design, high degree of automation the collection machine, electricity, gas in one of the new type of bottled water filling machine and pure water production line.